Animal Cell Culture Fundamentals: A Microbiologist's Guide to Mammalian Systems

This article provides microbiologists with a comprehensive guide to the principles and practices of animal cell culture.

Animal Cell Culture Fundamentals: A Microbiologist's Guide to Mammalian Systems

Abstract

This article provides microbiologists with a comprehensive guide to the principles and practices of animal cell culture. It bridges the knowledge gap from microbial systems by detailing the unique requirements of mammalian cells, including complex media, stringent aseptic techniques, and specialized equipment. The scope covers foundational concepts like primary cultures and cell lines, core methodologies for maintenance and cryopreservation, essential troubleshooting for contamination and culture health, and the critical importance of validation through cell line authentication and quality control. This serves as an essential primer for applying these techniques in biomedical research and drug development.

From Microbes to Mammalian Cells: Mastering Foundational Concepts

Defining Animal Cell Culture and Its Core Applications in Research and Bioproduction

Animal cell culture, a cornerstone technique in modern life sciences, involves the propagation of animal cells in a controlled artificial environment. This in-depth technical guide delineates the fundamental principles, methodologies, and quantitative landscape of animal cell culture, contextualized for microbiologists and drug development professionals. We detail core protocols for maintaining cell integrity from thawing to cryopreservation, summarize key market metrics and growth conditions in structured tables, and visualize critical workflows. Furthermore, we explicate the indispensable applications of this technology in biopharmaceutical manufacturing, vaccine production, and advanced research models, underscoring its pivotal role in translating basic biological insights into therapeutic and commercial outcomes.

Animal cell culture is defined as the process by which human, animal, or insect cells are grown in a favorable artificial environment outside their natural biological context [1]. This technology, which became a common laboratory technique in the mid-1900s, has evolved from a simple tool for maintaining live cell lines into a major platform driving innovation in life sciences and commercial biotechnology [1]. The foundational principle hinges on recreating in vivo conditions in vitro, providing a controlled system to study cell biology, disease mechanisms, and production of complex biological products [2] [3].

The historical development of animal cell culture dates back to the early 20th century. Key milestones include Ross Granville Harrison's 1907-1910 experiments demonstrating nerve fiber growth from frog embryonic tissue in clotted lymph, which established the basic methodology [1] [4]. The period between the 1940s and 1960s marked a significant acceleration, driven largely by the demand for viral vaccines. The development of the polio vaccine by Jonas Salk, enabled by the viral culture techniques of Enders, Weller, and Robbins, stands as a testament to this progress [1]. Today, mammalian cell culture is an indispensable prerequisite for manufacturing a wide array of biological therapeutics, including monoclonal antibodies, hormones, interferons, clotting factors, and vaccines [1].

For microbiologists, transitioning to animal cell culture requires a paradigm shift in aseptic technique and medium complexity. While microbial cultures often utilize simple, defined media, animal cell culture media are complex concoctions requiring a precise balance of amino acids, vitamins, salts, glucose, and growth factors, typically supplemented with serum or defined replacements to support cell survival and proliferation [2] [4]. The core challenge lies in maintaining a sterile, physiologically stable environment (typically 37°C, 5% CO2, and 95% relative humidity) for cells that are far more fastidious than most microorganisms [4] [5].

Technical Breakdown: Cell Types, Culture Models, and Workflows

Classification of Cell Cultures and Cell Lines

Cultures initiated directly from animal tissues are termed primary cultures. These are heterogeneous, slow-growing, and retain the characteristic number of chromosomes of the source tissue, but have a finite lifespan [2]. Primary cultures can be further classified as:

- Anchorage-dependent/Adherent cells: Require a solid, non-toxic surface for attachment and growth (e.g., kidney cells, fibroblast cells) [2].

- Anchorage-independent/Suspension cells: Can grow freely floating in the culture medium (e.g., hematopoietic cells, hybridomas) [2].

When a primary culture is subcultured (passaged), it becomes a cell line [6]. Cell lines are categorized based on their growth potential:

- Finite Cell Lines: Cells divide a limited number of times (typically 20-100 population doublings) before undergoing senescence [2]. An example is human fibroblast cultures like WI-38 [1].

- Continuous Cell Lines: These have acquired the ability to proliferate indefinitely (immortalization) either through random mutation or deliberate genetic modification [2]. They often emerge from tumor tissues or via transformation by chemicals or viruses. Examples include HeLa (human cervical carcinoma) and CHO (Chinese Hamster Ovary) cells [1] [2].

Essential Experimental Workflows

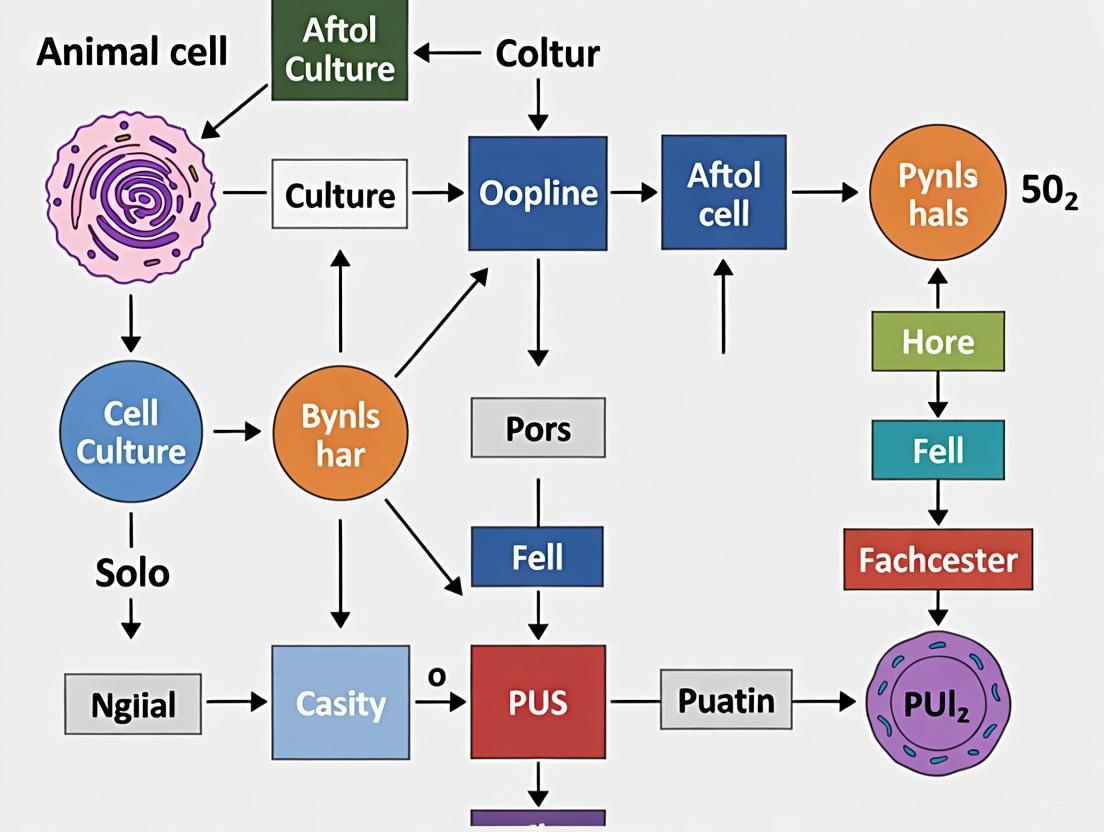

Mastering fundamental techniques is critical for cell culture integrity. The workflow below outlines the core process for handling adherent mammalian cells.

Workflow Diagram 1: Core adherent cell culture process.

Protocol: Thawing Cryopreserved Cells

Rapid thawing and removal of cryoprotectant are vital for cell viability [6].

- Preparation: Warm complete growth medium in a 37°C water bath. Prepare a culture vessel with the recommended volume of pre-equilibrated medium [5].

- Thawing: Remove vial from liquid nitrogen storage and immediately place in a 37°C water bath with gentle agitation. Thaw rapidly (~2 minutes) until only a small ice crystal remains [6].

- Decontamination: Spray or dip the vial in 70% ethanol and transfer to a biosafety cabinet [6].

- Dilution and Centrifugation: Transfer the cell suspension to a sterile centrifuge tube containing 9 mL of warm medium. Gently pipette to mix. Centrifuge at approximately 125 × g for 5-10 minutes to pellet cells and remove the cryoprotectant (DMSO) [6].

- Resuspension and Seeding: Discard the supernatant. Gently resuspend the cell pellet in 1-2 mL of fresh complete growth medium. Transfer the cell suspension to the prepared culture vessel and mix by gentle rocking [6] [5].

- Incubation: Place the culture vessel in a 37°C incubator with a humidified atmosphere of 5% CO2. Examine the cells after 24 hours and change the medium if necessary [6].

Protocol: Subculturing Adherent Cells (Passaging)

This process, also known as trypsinization, is used to split cells into new vessels before they reach 100% confluency to maintain exponential growth [6] [5].

- Remove Medium: Aspirate and discard the spent culture medium from the flask.

- Rinse: Wash the cell monolayer with a pre-warmed, sterile phosphate-buffered saline (PBS) to remove residual serum and calcium, which inhibit trypsin.

- Add Dissociation Reagent: Add enough pre-warmed trypsin-EDTA solution to cover the cell monolayer (e.g., 2-3 mL for a T-75 flask) [2].

- Incubate: Place the flask in a 37°C CO2 incubator for 1-3 minutes. Observe cells under a microscope until they round up and detach. Firmly tap the side of the flask to dislodge any remaining adherent cells [2].

- Neutralize: Add a volume of complete growth medium containing serum (which inhibits trypsin) that is at least double the volume of trypsin used. Pipette the solution across the surface to collect all cells and break up clumps.

- Count and Seed: Perform a cell count using a hemocytometer or automated cell counter. Seed an appropriate aliquot of the cell suspension into new culture vessels containing fresh, pre-warmed medium [5].

The Scientist's Toolkit: Essential Research Reagents

The following table catalogs fundamental reagents required for successful animal cell culture.

Table 1: Essential Reagents for Animal Cell Culture

| Reagent/Chemical | Core Function | Technical Notes |

|---|---|---|

| Basal Medium (e.g., DMEM, RPMI-1640) | Provides essential nutrients: amino acids, vitamins, carbohydrates, inorganic salts [4]. | Formulation must be selected based on cell type requirements. |

| Serum (e.g., Fetal Bovine Serum - FBS) | A complex, undefined supplement providing growth factors, hormones, and adhesion factors [4]. | Subject to batch-to-batch variability; potential source of contaminants. |

| Serum-Free & Chemically Defined Media | Eliminates variability of serum; supports specific cell types in a controlled environment [7] [8]. | Crucial for biomanufacturing consistency and specific applications like stem cell culture. |

| Trypsin/EDTA | Proteolytic enzyme (trypsin) disaggregates adherent cells; EDTA chelates calcium to enhance trypsin activity [2] [5]. | Exposure time must be optimized to avoid cellular damage. |

| Cryoprotectant (DMSO) | Prevents intracellular ice crystal formation during the freezing process, protecting cell viability [6]. | Must be removed promptly after thawing. |

| Antibiotics/Antimycotics | Used to prevent bacterial and fungal contamination in culture [2]. | Not a substitute for aseptic technique; can mask low-level contamination. |

| PBS (Phosphate Buffered Saline) | An isotonic salt solution used for washing cells and diluting reagents without causing osmotic shock. | Lacking calcium and magnesium, it is ideal for rinsing before trypsinization. |

| pH Indicator (Phenol Red) | Visual indicator of culture medium pH (yellow: acidic; red: normal; purple: basic) [4]. | A color change can indicate microbial contamination or metabolic stress. |

Quantitative Data and Market Landscape

The animal cell culture market is a multi-billion dollar industry, characterized by robust growth and significant commercial investment. The following tables summarize key quantitative data.

Table 2: Animal Cell Culture Market Metrics and Forecasts

| Metric | Value/Range | Context & Timeframe |

|---|---|---|

| Global Market Value (Est.) | ~USD 15 Billion [8] | Base Year 2023 |

| Projected CAGR | 8% - 11.3% [7] [8] | Forecast Period 2025-2032 |

| North America Market Share | ~40% [7] | Largest regional market, driven by strong biopharma R&D. |

| Biopharmaceutical Manufacturing Segment Share | ~65% [8] | Largest application segment (therapeutic proteins, mAbs, vaccines). |

| Leading Company Market Concentration | ~60% shared by Life Technologies, Thermo Fisher, Merck Millipore, Corning [8] | Reflects an oligopolistic market structure. |

Table 3: Standard Mammalian Cell Culture Conditions and Parameters

| Parameter | Typical Setting | Notes |

|---|---|---|

| Temperature | 37°C [4] | Mimics core body temperature for human and many mammalian cells. |

| CO2 Concentration | 5% [4] | Works with bicarbonate buffer in media to maintain physiological pH (~7.4). |

| Relative Humidity | 95% [4] | Preents evaporation of culture medium. |

| Growth Medium pH | 7.2 - 7.4 [4] | Critical for enzyme function and cell health; monitored via phenol red. |

Core Applications in Research and Bioproduction

Biopharmaceutical Manufacturing

Animal cell culture is indispensable for producing complex, glycosylated therapeutic proteins that cannot be synthesized in microbial systems like E. coli [1] [3]. Chinese Hamster Ovary (CHO) cells are the predominant industrial workhorse due to their robustness in suspension culture and ability to perform human-compatible post-translational modifications [3]. Key product classes include:

- Monoclonal Antibodies (mAbs): Used for treating cancer, autoimmune diseases, and infectious diseases [1] [3]. Industrial antibody titers can now exceed 5 g/L in optimized processes [1].

- Hormones and Enzymes: Examples include recombinant insulin for diabetes and erythropoietin (EPO) for anemia [1] [3].

- Other Therapeutic Proteins: Including clotting factors for hemophilia, interferons, and interleukins [1] [2].

Vaccine Production

The technique is fundamental to modern virology and vaccine development. Cell-based methods have largely replaced egg-based production for many viruses, offering faster scalability and reduced risk of allergic reactions [1] [3]. Viral vaccines for diseases such as chicken pox, polio, rabies, hepatitis B, and measles are produced using mass culturing of animal cell lines [1]. The recent COVID-19 pandemic underscored the value of cell culture platforms for rapid pandemic response.

Basic and Translational Research

Cell cultures provide a simplified, controlled model system for a wide range of research applications:

- Cancer Research: Cultures are used to characterize cancer cells and study the role of chemicals, viruses, and radiation in carcinogenesis [1] [2].

- Drug Screening and Toxicity Testing: Cell-based assays are used to study the effects and toxicity of new drug candidates, providing a bridge between in vitro biochemical assays and complex in vivo models [1] [3].

- Gene Therapy: Animal cell cultures are used for the development and testing of gene-modifying techniques, where cells with defective genes are replaced with functional ones [1] [2].

- Model Systems: They are vital for studying basic cell biology, cell cycle mechanisms, specialized cell function, and cell-cell interactions [1].

Emerging Trends and Future Perspectives

The field of animal cell culture is dynamic, with several advanced technologies shaping its future:

- 3D Cell Culture and Organ-on-a-Chip (OOC): These technologies aim to better mimic the in vivo microenvironment by growing cells in three-dimensional structures, often under perfusion. A 2023 meta-analysis concluded that while gains from perfusion in standard 2D cultures are modest, 3D cultures show a slight but significant improvement under flow, suggesting that high-density cultures benefit from enhanced mass transport [9]. OOCs are used to model organs like the intestine, liver, and lung for more physiologically relevant drug screening and disease modeling [9].

- Advanced Media Formulations: The shift towards serum-free and chemically defined media continues, driven by the need for consistency, reduced contamination risk, and compliance with regulatory requirements [8].

- Automation and High-Throughput Processing: Integration of automation, single-use bioreactor technologies, and artificial intelligence (AI) for process optimization is enhancing efficiency, scalability, and reproducibility in both research and bioproduction settings [7] [8].

- Cell and Gene Therapies: The rise of advanced therapeutic medicinal products (ATMPs), including CAR-T cells and other genetically modified cell therapies, is creating new demands and driving innovation in cell culture scale-up and manufacturing processes [8].

The foundation of modern microbiological and biomedical research rests heavily on the ability to culture and study animal cells in vitro. For researchers and drug development professionals, the choice of cellular model is a critical first step that directly influences the physiological relevance, reproducibility, and translational potential of experimental data. This decision most frequently centers on selecting between two fundamental systems: primary cell cultures and immortalized cell lines [10]. Primary cells are isolated directly from human or animal tissues and undergo minimal manipulation, preserving the original characteristics and functions of the tissue of origin [11] [12]. In contrast, immortalized cell lines are populations of cells that have acquired the ability to proliferate indefinitely, either through intentional genetic modification or as a result of spontaneous mutation in cancer-derived cells [11] [13]. The core distinction of "finite vs. infinite growth" underpins every aspect of their use, from experimental design to data interpretation. This guide provides an in-depth technical comparison of these systems, framing them within the broader context of animal cell culture basics for microbiological research.

Core Principles and Fundamental Differences

Defining the Cellular Models

Primary Cell Cultures are initiated directly from tissue obtained from a human donor or animal. The isolation process involves mechanical or enzymatic dissociation of the tissue into a single-cell suspension, which is then placed in a culture vessel with a suitable growth medium [10] [12]. These cultures are considered primary from the point of isolation until their first subculture. Once passaged, they become a cell line [10]. Primary cells are finite; they undergo a limited number of population doublings (typically up to 10) before entering a state of senescence, where they remain metabolically active but cease to divide [10] [12]. Their key advantage is the retention of genetic and phenotypic stability and a close match to in vivo function, making them highly physiologically relevant [11] [14].

Immortalized Cell Lines are derived from primary cultures that have undergone a transformative genetic event, allowing them to escape senescence and proliferate indefinitely [12]. This transformation can occur spontaneously, often in cultures derived from tumor tissue (e.g., HeLa cells from cervical cancer), or be induced deliberately via viral genes or the introduction of oncogenes [11] [13]. These infinite cells are the workhorses of many laboratories due to their robustness, ease of culture, and ability to be expanded without limitation [15] [16]. However, this very transformation means they may lack key functions or characteristics of normal cells and often shift their cellular resources towards proliferation, which can compromise their biological relevance [11] [16].

The following table summarizes the critical differences between primary cells and immortalized cell lines, providing a clear, quantitative comparison for researchers.

Table 1: Comprehensive Comparison of Primary Cells and Immortalized Cell Lines

| Feature | Primary Cells | Immortalized Cell Lines |

|---|---|---|

| Origin & Definition | Isolated directly from donor tissue [11] | Derived from tumors or intentionally immortalized [11] |

| Lifespan | Finite (limited population doublings) [11] [12] | Infinite (can proliferate indefinitely) [11] |

| Physiological Relevance | High; closely resembles in vivo cell function [11] [14] | Low to moderate; may lack key functions, often cancer-derived [11] [15] |

| Genetic & Phenotypic Stability | High genomic stability, but can drift with passaging [14] [10] | Subject to genetic drift and proteomic changes with continuous culture [14] [16] |

| Donor Characteristics | Retained (e.g., HLA type, CMV status, disease state) [11] [14] | Not available [11] |

| Reproducibility & Variability | High donor-to-donor variability [15] | Highly reproducible, but prone to cross-contamination and misidentification [14] |

| Maintenance Difficulty | High; require optimized conditions, more fastidious [10] [12] | Low; robust, easy to culture and maintain [10] [15] |

| Cost & Scalability | High cost, limited scalability [15] | Low cost, highly scalable for high-throughput studies [15] |

| Typical Applications | Disease modeling, drug toxicity testing, immunology, metabolic studies [11] [12] | High-throughput screening, functional genomics, basic mechanistic studies, vaccine production [11] [15] [16] |

The choice between these systems involves a direct trade-off. Primary cells offer biological fidelity at the expense of practicality and scalability, while immortalized cell lines offer practical convenience at the expense of physiological relevance [15]. This trade-off is visually summarized in the following decision-making workflow.

Detailed Methodologies and Experimental Protocols

Establishing and Maintaining Primary Cultures

The process of creating a primary cell culture is technically demanding and requires meticulous attention to detail to preserve cell viability and function.

A. Isolation and Initial Culture: The foundational step is the dissociation of tissue. The digestion method uses proteolytic enzymes like trypsin or collagenase to break down the extracellular matrix, creating a single-cell suspension [10]. The tissue explant method involves mincing tissue into small fragments and allowing cells to migrate out from these fragments onto the culture vessel surface, which is often pre-coated with collagen to enhance attachment [10]. For inherently non-adherent cells like those from blood or bone marrow, suspension culture is used, typically involving density gradient centrifugation for separation [10]. Upon isolation, cells are resuspended in a specialized growth medium. This medium is typically supplemented with serum (e.g., Fetal Bovine Serum) to provide growth factors and other essential components, and often includes antibiotics like penicillin/streptomycin initially to prevent contamination from the host tissue [12]. The culture is incubated at 37°C in a humidified atmosphere with 5% CO₂ to maintain physiological pH [13] [12].

B. Maintenance and Passaging: Primary cells are typically passaged when they reach 80-90% confluency, before they contact-inhibit and potentially differentiate [12]. The process for adherent cells involves:

- Washing with a balanced salt solution to remove serum residues.

- Digestion using a low concentration of trypsin/EDTA to disrupt cell-cell and cell-substrate bonds. The trypsinization process is temperature-sensitive and must be carefully monitored to avoid over-digestion, which can damage cell surface receptors [10].

- Neutralization of the trypsin using serum-containing medium.

- Centrifugation and resuspension in fresh medium for seeding into new culture vessels at an appropriate density [12].

C. Cryopreservation and Recovery: For long-term storage, primary cells are cryopreserved using a controlled-rate freezer. The standard cryopreservation medium consists of a mixture of 80% complete growth medium, 10% FBS, and 10% DMSO as a cryoprotectant [12]. Cells are frozen at a slow rate of -1°C per minute to minimize the formation of lethal intracellular ice crystals and stored in liquid nitrogen or its vapor phase [12]. Upon thawing, a rapid process in a 37°C water bath is critical. It is recommended to seed the cells immediately after thawing and replace the medium containing DMSO within 24 hours, as DMSO can be toxic to primary cells upon prolonged exposure [12].

Characterizing Immortalized Cell Lines

While immortalized cells are easier to maintain, their identity and stability must be actively managed to ensure experimental integrity.

A. Authentication and Contamination Control: A significant risk with continuous cell lines is misidentification and cross-contamination [14]. A prominent example is the widespread contamination of various cell lines with HeLa cells [14]. To combat this, guidelines, including those from leading journals, now recommend Short Tandem Repeat (STR) profiling as a genetic fingerprint to authenticate cell lines [14] [10]. Furthermore, routine screening for mycoplasma and other microbial contaminants is essential, as studies have found a significant portion of cell lines to be contaminated, which can drastically alter cell physiology and experimental outcomes [14].

B. Assessing Functional Phenotype: Given their adapted nature, it is crucial to understand how an immortalized cell line differs functionally from its primary counterpart. Quantitative proteomic techniques, such as SILAC (Stable Isotope Labeling by Amino acids in Cell culture), can be employed to compare the proteomes of cell lines and primary cells [16]. This methodology allows for the identification of specific functional deficits. For instance, a comparative study of the Hepa1-6 hepatoma cell line and primary hepatocytes revealed that the cell line had a deficiency in mitochondrial proteins, a drastic up-regulation of cell cycle functions, and a shutdown of key liver-specific drug-metabolizing enzymes [16]. This kind of analysis provides a rational basis for determining if a cell line is suitable for a particular research question.

The Scientist's Toolkit: Essential Research Reagents

Successful cell culture, whether primary or immortalized, relies on a suite of essential reagents and materials. The following table details key components of a researcher's toolkit.

Table 2: Key Reagents and Materials for Cell Culture Research

| Reagent/Material | Function/Purpose | Technical Notes |

|---|---|---|

| Culture Vessels (flasks, plates) | Provide a sterile, biocompatible surface for cell growth. | Treated plastic for adherent cells; specialized low-attachment plates for suspension or 3D cultures [13]. |

| Basal Medium (e.g., DMEM, RPMI-1640) | Provides essential nutrients, salts, and energy sources (glucose). | The foundation to which supplements are added [13] [12]. |

| Serum (e.g., Fetal Bovine Serum - FBS) | Source of growth factors, hormones, lipids, and attachment factors. | Introduces variability; defined serum-free media are preferred for consistent results [13] [12]. |

| Antibiotics/Antimycotics (e.g., Penicillin/Streptomycin) | Prevent bacterial and fungal contamination. | Use is recommended for primary isolation but can be avoided in established, sterile cultures to avoid masking low-level contamination [12]. |

| Dissociation Agents (e.g., Trypsin, Collagenase) | Enzymatically digest extracellular matrix to dissociate tissues or detach adherent cells for passaging. | Concentration and incubation time must be optimized to prevent cell damage [10] [12]. |

| Cryoprotectant (e.g., DMSO) | Prevents intracellular ice crystal formation during freezing. | Must be removed promptly after thawing due to potential cytotoxicity [12]. |

| Extracellular Matrix (ECM) Coatings (e.g., Collagen, Matrigel) | Mimics the natural cellular environment, enhancing attachment, proliferation, and differentiation. | Crucial for culturing sensitive primary cells and for 3D culture models like organoids [10] [13]. |

| Buffering Systems (e.g., HEPES) | Maintains physiological pH (approx. 7.4) in the culture medium. | HEPES is useful for procedures outside a CO₂ incubator, while the CO₂/bicarbonate system is standard within an incubator [13] [12]. |

Application Scenarios and Decision Framework

The strengths and weaknesses of primary cells and cell lines make them suited for different stages and types of research. The following diagram maps their application across the drug discovery and development pipeline, illustrating how they can be used complementarily.

Primary Cells are indispensable in applications where physiological relevance is paramount. They are the gold standard for:

- Drug Screening and Toxicity Testing: Evaluating the efficacy and safety of new drug candidates in a system that closely mimics the human in vivo response [14] [12].

- Disease Modeling: Studying the pathophysiology of diseases using cells derived from patients, allowing for the investigation of specific genetic backgrounds and disease mechanisms [12].

- Immunology and Vaccine Development: Investigating immune cell function, signaling, and response to pathogens or vaccines, as they retain their native receptors and functions [11].

- Advanced 3D Models: Serving as the building blocks for more complex ex vivo systems like organoids and organs-on-chips, which better recapitulate tissue structure and function [13].

Immortalized Cell Lines excel in projects that require scale, consistency, and genetic tractability:

- Large-Scale Functional Genomics: Genome-wide siRNA or CRISPR screens to identify gene functions, where millions of identical cells are required [15] [16].

- Biomolecule Production: Large-scale production of proteins, antibodies, and vaccines (e.g., polio, rabies) due to their infinite expandability [12].

- Basic Mechanistic Studies: Investigating fundamental cellular processes like the cell cycle, where their robustness and reproducibility are advantageous [16].

The dichotomy between finite primary cells and infinite immortalized lines represents a fundamental compromise in biological research: fidelity versus convenience. While primary cells provide a window into native human (or animal) biology, their practical limitations are significant. Conversely, the robustness and scalability of immortalized cell lines are offset by their often poor predictive power for human physiology, contributing to high failure rates in drug development, particularly in complex areas like central nervous system diseases [15].

The future of in vitro modeling is being shaped by technologies that aim to bridge this gap. Human-induced pluripotent stem cells (iPSCs) represent a powerful alternative, as they can be renewed indefinitely like cell lines and differentiated into human-specific somatic cells [13] [15]. Furthermore, deterministic reprogramming technologies, such as the opti-ox platform, are emerging to address the batch-to-batch variability and lengthy differentiation processes associated with traditional iPSC workflows. These systems can generate consistent, scalable, and functionally validated human cells (ioCells) designed to combine the physiological relevance of primary cells with the reproducibility and ease of use of cell lines [15]. As regulatory bodies like the FDA begin to endorse such New Approach Methodologies (NAMs), the field is moving toward a future where researchers will no longer have to choose between biological relevance and practical utility, thereby accelerating the translation of basic research into effective clinical applications [15].

The foundation of many advances in biologics, gene therapy, and drug discovery rests upon the robust cultivation of animal cells. For microbiologists transitioning into mammalian cell culture systems, understanding the fundamental distinction between adherent and suspension cultures is paramount. These are not merely different technical approaches but represent distinct biological states that profoundly impact cellular morphology, function, and experimental outcomes. Adherent cell cultures proliferate by attaching to a solid, growth-promoting substrate, a property known as "anchorage dependence" [17]. In contrast, suspension cell cultures reproduce freely while suspended in the culture medium, without attachment to any surface [18]. This dichotomy in growth requirement dictates every subsequent aspect of experimental design, from vessel selection and medium formulation to passaging protocols and scaling potential. The choice between these systems is often dictated by the cell line's innate characteristics, the required yield, and the final application, whether for basic research, viral vector production, or therapeutic protein manufacturing [19] [20].

Core Principles and Morphological Characteristics

Defining Adherent Cell Culture

Adherent cells require a solid, biologically compatible surface for attachment and proliferation. This anchorage dependence is a characteristic of many primary cells and cell lines derived from tissues that naturally function in a stationary, structured environment in vivo, such as fibroblasts and epithelial cells [6]. The attachment process is mediated by cell surface receptors that interact with specific proteins on the substrate, leading to cytoskeletal reorganization and the characteristic spread morphology of adherent cells. A key feature of adherent culture is contact inhibition; once the cells have proliferated to cover the entire available surface (reached confluency), they cease dividing [6]. This necessitates a subculturing process, known as passaging, to detach a portion of cells and seed them into a new vessel to maintain exponential growth.

Defining Suspension Cell Culture

Suspension cells grow and multiply freely floating in the culture medium. This growth mode is typical of cells derived from blood, such as lymphocytes, and certain immortalized cell lines (e.g., HL-60, WEHI-231) that have lost their anchorage requirement [18]. Because they are not limited by surface area, suspension cultures can achieve much higher cell densities in a given volume compared to adherent systems. They are maintained by diluting the culture with fresh medium once the cell concentration reaches a predetermined maximum, a process simpler than the enzymatic detachment required for adherent cells [18]. This makes them inherently more scalable, which is a critical advantage for industrial bioprocessing.

Comparative Analysis: Morphology and Growth Dynamics

The physical growth requirements directly translate to distinct morphological and behavioral characteristics, summarized in the table below.

Table 1: Core Characteristics of Adherent vs. Suspension Cultures

| Feature | Adherent Culture | Suspension Culture |

|---|---|---|

| Growth Requirement | Requires attachment to a solid substrate (anchorage-dependent) [17]. | Grows freely floating in the medium (anchorage-independent) [18]. |

| Cell Morphology | Spread, flattened, and elongated shapes; strong cell-surface and cell-cell interactions [21]. | Typically spherical or rounded morphology; growth as single cells or small aggregates [18]. |

| Growth Surface | Requires tissue-culture (TC) treated vessels (e.g., red-coded standard or yellow-coded Cell⁺ surfaces) [22]. | Uses non-TC-treated, hydrophobic vessels (e.g., green-coded surfaces) to prevent attachment [22]. |

| Passaging Method | Enzymatic (e.g., trypsin) or non-enzymatic dissociation reagent required for detachment [17]. | Simple dilution of the cell suspension into fresh medium; no detachment needed [18]. |

| Confluence Check | Microscopic observation of monolayer coverage [17]. | Medium appears turbid (cloudy) when the culture flask is swirled [18]. |

| Scalability | Scaled out by increasing surface area (e.g., more flasks, multi-layered vessels) [19]. | Scaled up by increasing culture volume (e.g., larger bioreactors) [19]. |

| Typical Applications | Primary cells, cell lines for viral plaque assays, epithelial and fibroblast studies [21]. | Production of recombinant proteins, antibodies, and viral vectors; hematopoetic cell studies [19]. |

Experimental Protocols for Culture Maintenance

Subculturing Adherent Cells

The passaging of adherent cells is a critical skill for maintaining healthy, proliferative cultures. The following protocol details the standard procedure using a dissociation reagent like trypsin [17].

Table 2: Materials for Adherent Cell Passaging

| Material/Reagent | Function |

|---|---|

| Complete Growth Medium | Provides nutrients, growth factors, and serum to support cell growth. Pre-warmed to 37°C. |

| Balanced Salt Solution (without Ca2+/Mg2+) | Washes away residual serum and divalent cations that inhibit trypsin. |

| Dissociation Reagent (e.g., Trypsin) | Proteolytic enzyme that digests adhesion proteins, detaching cells from the surface. |

| Trypan Blue Stain | Dye used with a hemocytometer or automated cell counter to determine cell viability and count. |

Step-by-Step Protocol [17]:

- Confirm Cell Confluency: Visually inspect cells under a microscope. Passage when they are 80-90% confluent and in the log phase of growth, with viability >90%.

- Remove Spent Medium: Aspirate and discard the used culture medium from the vessel.

- Wash Cell Layer: Gently add a balanced salt solution (without calcium and magnesium) to the side of the vessel opposite the cell layer. Rock the vessel to wash the cells, then aspirate and discard the solution. This step removes serum that would inhibit trypsin.

- Add Dissociation Reagent: Add pre-warmed dissociation reagent (e.g., trypsin) to cover the cell layer. Gently rock the vessel for complete coverage.

- Incubate: Incubate the vessel at room temperature for approximately 2 minutes (time varies by cell line).

- Check for Detachment: Observe under a microscope. If less than 90% of cells are detached (rounded and floating), tap the vessel gently and continue incubation, checking every 30 seconds.

- Neutralize Reaction: When most cells are detached, add a volume of complete growth medium that is at least double the volume of trypsin used. Pipette the medium over the cell layer surface to dislodge any remaining cells and neutralize the enzyme.

- Centrifuge: Transfer the cell suspension to a centrifuge tube and spin at approximately 200 x g for 5-10 minutes.

- Resuspend and Count: Discard the supernatant and resuspend the cell pellet in a small volume of fresh medium. Take a sample to count cells and assess viability using trypan blue.

- Seed New Flasks: Dilute the cell suspension to the recommended seeding density and pipette into new culture vessels. Return the vessels to the incubator.

Subculturing Suspension Cells

Maintaining suspension cells is generally less labor-intensive, as it does not require a detachment step. The protocol focuses on controlling cell density to keep cells in the exponential growth phase [18].

Step-by-Step Protocol [18]:

- Assess Culture Density: Check the culture for turbidity (cloudiness) and the presence of cell clumps. If cells have settled, swirl the flask to resuspend them evenly.

- Sample and Count: Aseptically remove a small sample of the cell suspension. Determine the total cell count and percent viability using an automated cell counter or hemocytometer with trypan blue.

- Calculate Dilution: Calculate the volume of fresh, pre-warmed growth medium needed to dilute the culture down to the recommended seeding density for the cell line.

- Passage the Culture: Aseptically add the required volume of fresh medium into the culture flask. Alternatively, you can centrifuge the culture (e.g., 10 minutes at 800 x g) to remove the spent medium and metabolic waste, then resuspend the cell pellet in a fresh, appropriate volume of medium [18].

- Maintain Gas Exchange: For shaker flasks, loosen the caps one full turn. For spinner flasks, loosen the side arm caps to allow for proper gas exchange before returning them to the incubator or shaker.

The workflow for handling both culture types is fundamentally different, as illustrated below.

The Scientist's Toolkit: Essential Reagents and Materials

Successful cell culture relies on a suite of specialized reagents and materials. The selection is often specific to the culture type.

Table 3: Essential Research Reagent Solutions for Cell Culture

| Item | Function | Adherent Culture | Suspension Culture |

|---|---|---|---|

| Culture Vessels | Provides the environment for cell growth. | TC-treated flasks/dishes/plates (Red: Standard; Yellow: Cell⁺ for sensitive cells) [22]. | Non-TC-treated, hydrophobic flasks (Green-coded); spinner or shaker flasks [18] [22]. |

| Complete Growth Medium | Provides nutrients, energy, and essential growth factors. | Formulated with serum or defined supplements; often contains calcium to promote adhesion. | Serum-free or serum-containing; may lack calcium to minimize aggregation; may contain surfactants (e.g., Pluronic F-68) to reduce shear [18]. |

| Dissociation Reagent | Detaches adherent cells for subculturing. | Essential (e.g., trypsin, TrypLE) [17]. | Not required for routine passaging. |

| Cell Counter & Viability Stain | Determines cell concentration and health. | Essential for determining seeding density (e.g., hemocytometer, automated counter with Trypan Blue) [17]. | Essential for determining dilution ratio (e.g., hemocytometer, automated counter with Trypan Blue) [18]. |

| Centrifuge | Pellet cells for medium change or after detachment. | Used after trypsinization to remove the dissociation reagent [17]. | Used periodically to remove waste products and refresh medium [18]. |

Scaling and Industrial Applications: A Case-Based Analysis

The choice between adherent and suspension systems becomes critically strategic when moving from laboratory research to industrial-scale manufacturing, particularly in the field of viral vector production for gene therapies.

Scale-Up Philosophies and Economic Drivers

The scalability of a process is a major determinant of its commercial viability. Adherent cultures are typically scaled out by increasing the available surface area, for instance, by using more roller bottles, multi-layered stacks (e.g., Cell Factories), or fixed-bed bioreactors (e.g., iCELLis) [19]. While this is effective, it can become labor-intensive, space-consuming, and challenging for ensuring batch-to-batch consistency at very large scales. In contrast, suspension cultures are scaled up by simply increasing the volume in stirred-tank bioreactors (STRs), a well-established and highly efficient method in traditional biologics [19]. This allows for a much higher volumetric cell density and is generally more amenable to process automation and monitoring.

Case Studies in Viral Vector Manufacturing

The industry currently employs both platforms, with the choice often dictated by the specific product and stage of development.

Adherent Platform Success:

- Zolgensma (Novartis): This AAV9-based gene therapy for spinal muscular atrophy is manufactured using an adherent HEK293 process in an iCELLis fixed-bed bioreactor. This platform was deemed a commercially viable solution, demonstrating that adherent processes can be successfully scaled [19].

- Luxturna (Spark Therapeutics/Roche): This AAV2-based therapy also uses an adherent HEK293 process in roller bottles, a classic scale-out approach suitable for its required dosage and patient population size [19].

Suspension Platform Adoption:

- Glybera (UniQure): This was the first Western-approved gene therapy to use a suspension-based process. The switch from an initial adherent process to suspension HEK293 cells was driven by the need for higher vector quantities [19].

- Industry Trend: Many companies, including pioneers like Bluebird Bio, have explicitly stated intentions to adapt their manufacturing processes from adherent to suspension platforms for certain products to achieve better scalability and cost-effectiveness [19].

Molecular Insights from HEK293 Adaptation

The transition of cell lines like HEK293 from adherent to suspension growth is not merely a change in protocol but involves underlying molecular adaptations. Genomic and transcriptomic analyses of various HEK293 derivatives have revealed significant changes in gene expression associated with cellular component organization, cell motility, and cell adhesion between adherent and suspension subtypes [20]. Furthermore, specific metabolic pathway switching, such as in cholesterol biosynthesis, and the differential expression of key genes (including RARG, ID1, and ZIC1), have been identified as hallmarks of the suspension-adapted phenotype [20]. This molecular understanding is crucial for rationally designing and optimizing cell lines for large-scale bioproduction.

The decision to utilize an adherent or suspension culture system is a foundational one that resonates through every aspect of a research or production workflow. Adherent cultures, with their anchorage-dependent growth and characteristic spread morphology, are indispensable for studying many primary cells and tissue-specific functions. Suspension cultures, characterized by their anchorage-independent, free-floating growth, offer unparalleled advantages in scalability and ease of handling for industrial bioprocessing. As the field of biologics and gene therapy advances, the ability to adapt processes to suspension-based platforms is increasingly viewed as critical for commercial success. However, as evidenced by current marketed products, well-optimized adherent processes remain viable and important. A deep understanding of the morphological, procedural, and molecular distinctions between these two systems empowers scientists to make informed decisions, optimize culture conditions, and robustly scale their processes to meet the demands of modern biotechnology.

For microbiologists venturing into the realm of animal cell culture, the familiar principles of microbiology serve as a foundation, but the specific requirements diverge significantly. The core challenge lies in the fundamental biological differences: microbial cells are often prokaryotic, self-sufficient, and robust, whereas mammalian cells are eukaryotic, fastidious, and require a highly complex and controlled environment to mimic their natural in vivo conditions [23]. This guide provides a detailed, technical comparison of the nutrient, environmental, and equipment needs for these two distinct cell culture systems, framing the information within the context of adapting a microbiologist's existing knowledge and skills. Understanding these contrasts is crucial for successful experimental outcomes in fields like drug development, biopharmaceutical production, and basic biological research.

Core Differences in Culture Media and Nutrients

The composition of culture media is the most pronounced difference between these two systems, directly reflecting the differing metabolic and biosynthetic capabilities of the cells.

Media Composition: A Side-by-Side Comparison

The table below summarizes the key compositional differences in media designed for microbial versus mammalian cell culture.

Table 1: Core Compositional Differences in Culture Media

| Component | Microbial Culture Media [24] [25] | Mammalian Cell Culture Media [26] [25] |

|---|---|---|

| Carbon Source | Often simple sugars (e.g., glucose) for energy. | Glucose, but also other carbon sources; part of a complex energy matrix. |

| Nitrogen Source | Inorganic (e.g., ammonium salts, nitrates) or simple organic sources. | Primarily organic, from amino acids and complex protein hydrolysates. |

| Growth Factors | Generally not required; cells synthesize their own. | Essential. Provided by serum (e.g., FBS) or defined additives like specific hormones and growth factors. |

| Buffering System | Often relies on salts within the medium. | CO₂-bicarbonate system is common, requiring a controlled CO₂ atmosphere (typically 5-10%) in incubators [27]. |

| pH Indicator | May be present. | Commonly uses phenol red, which transitions from yellow (acidic) to red (basic) over pH 6.2–8.2 [25]. |

| Additional Components | Selective agents (antibiotics, dyes) for isolating specific microbes. | Antibiotics (e.g., Penicillin-Streptomycin) to prevent bacterial contamination [25]. Attachment factors (e.g., collagen) for adherent cells. |

Media Formulation and Selection

The historical development and philosophy behind media formulation also differ. Microbial media can range from defined minimal media, containing only the bare essentials for growth, to complex media containing poorly defined mixtures like yeast or meat extracts, which support a wide variety of microbes [24] [25]. The choice depends on whether the goal is to select for specific microbes or to promote broad growth.

In contrast, mammalian cell culture media are inherently complex. The field has evolved from using natural media (e.g., plasma, tissue extracts) to a variety of synthetic media formulations [26]. These are categorized based on the presence of undefined components:

- Serum-Containing Media: Supplemented with animal serum (e.g., Fetal Bovine Serum, FBS), which provides a wide range of growth factors, hormones, and attachment factors. While highly effective for many cell types, it introduces batch-to-batch variability and undefined conditions [26].

- Serum-Free Media (SFM): Formulated with defined supplements (e.g., bovine serum albumin, growth factors) to replace serum, improving reproducibility and facilitating downstream processing.

- Chemically Defined Media: Contain only highly purified ingredients and recombinant proteins, offering the highest level of reproducibility and control, which is critical for biopharmaceutical manufacturing [26].

For a microbiologist, this shift means moving from media that controls which cells grow to media that meticulously supports the survival of a single, specific cell type.

Environmental and Physical Conditions

The physical environment required for cultivation is another area of stark contrast, driven by the different origins of the cells.

Key Environmental Parameters

Table 2: Comparison of Critical Environmental Conditions

| Parameter | Microbial Culture | Mammalian Cell Culture |

|---|---|---|

| Temperature | Variable, often 25°C - 37°C, depending on the microbe's natural habitat. | Strictly 36°C - 37°C for most mammalian cells to mimic core body temperature [27]. |

| pH | Can tolerate a broader range, often optimized for specific organisms. | Narrow range, typically pH 7.2 - 7.4, tightly regulated by a CO₂-bicarbonate buffer system [27] [25]. |

| Osmotic Pressure | Controlled by salts in the medium. | Critical and sensitive; requires a carefully balanced isotonic solution. |

| Oxygen Requirements | Varies greatly (aerobic, anaerobic, facultative). Can often tolerate higher dissolved oxygen tensions. | Most are aerobic, but require precise dissolved oxygen control; high shear stress from sparging can damage cells [28]. |

Growth Dynamics and Observation

Microbial growth in liquid media often leads to visible turbidity, which can be quantified with a spectrophotometer. On solid media, they form distinct, macroscopic colonies.

Mammalian cells, however, require microscopic observation. Their growth phases—lag, log (exponential), stationary, and decline—are analogous to microbial growth curves but are tracked differently [6]. Adherent cells must be observed under an inverted microscope to assess confluency (the percentage of the growth surface covered by cells), which determines when they need to be subcultured [6]. Suspension cells are monitored for cell concentration and viability using dyes like Trypan Blue and counted with a hemocytometer or automated cell counter [29] [30].

Diagram: Mammalian cell growth requires passaging to maintain health.

Essential Laboratory Equipment and Setup

While a microbiologist's lab will have familiar equipment, the emphasis and specific types of tools required for mammalian cell culture are distinct and non-negotiable for maintaining aseptic and controlled conditions.

Equipment Comparison and Purpose

Table 3: Contrasting Key Laboratory Equipment

| Equipment | Role in Microbiology | Role in Mammalian Cell Culture |

|---|---|---|

| Containment Cabinet | A laminar flow hood may be used for sterility, but its primary purpose is to protect the sample from contaminants [31]. | A Biosafety Cabinet (BSC Class II) is essential. It protects the sample from contamination and protects the user from biohazards using HEPA-filtered exhaust air [31] [29]. |

| Incubator | Often a simple dry-heat incubator set to a specific temperature. | A humidified CO₂ incubator is mandatory to precisely control temperature, CO₂ (for pH balance), and high humidity (to prevent evaporation) [27] [29]. |

| Microscope | Standard compound microscope for viewing stained slides. | An inverted microscope is standard for viewing adherent cells in flasks and plates without disturbing them [30]. |

| Preservation | Short-term refrigeration or freezing; long-term at -80°C or freeze-drying. | Cryopreservation in liquid nitrogen (-130°C to -196°C) is essential for long-term storage of most cell lines to maintain genetic and phenotypic stability [29] [6]. |

| Cell Counter | Spectrophotometer for measuring turbidity (optical density). | Hemacytometer or automated cell counter is used to count cells and assess viability (live/dead ratio) before experiments [29] [30]. |

The Aseptic Workflow and Contamination Control

The consequence of contamination is far more catastrophic in mammalian cell culture. Whereas a bacterial culture might overcome a minor fungal spore contamination, the same contaminant will typically obliterate a mammalian cell culture. Furthermore, mammalian cells can be infected by mycoplasma, a type of bacteria that does not cause turbidity and is invisible under a standard microscope, requiring specialized PCR or staining techniques for detection [6].

This necessitates rigorous aseptic technique, which goes beyond standard microbiological practice. Key measures include:

- Working exclusively within a BSC that has been properly sterilized with ethanol before and after use.

- Using antibiotic-containing media judiciously (as a backup, not a substitute for aseptic technique).

- Routinely checking cells for contamination (bacterial, fungal, and mycoplasma).

- Creating master and working cell banks to preserve low-passage cells [6].

Diagram: The core mammalian cell culture workflow relies on specialized equipment.

Strategic Applications in Bioprocessing

The choice between microbial and mammalian systems is strategic, driven by the nature of the desired biologic product.

- Microbial Fermentation is favored for producing smaller, non-glycosylated molecules such as peptides, cytokines, growth factors, plasmid DNA (pDNA), and antibody fragments. Its advantages include shorter process times, higher production yields, and lower costs [23]. Organisms like E. coli and S. cerevisiae are well-established workhorses.

- Mammalian Cell Culture is the dominant platform for producing large, complex proteins that require specific post-translational modifications, most notably glycosylation. This includes monoclonal antibodies (mAbs), recombinant hormones, and many viral vaccines. Chinese Hamster Ovary (CHO) cells are the most commonly used mammalian host [23]. While more expensive and time-consuming, they are often the only system that can produce a functionally active product.

The Scientist's Toolkit: Essential Reagents and Materials

For the microbiologist transitioning to mammalian cell culture, familiarity with the following core reagents is critical.

Table 4: Essential Reagent Toolkit for Mammalian Cell Culture

| Reagent/Material | Function | Notes for Microbiologists |

|---|---|---|

| Basal Medium (e.g., DMEM, RPMI-1640) [26] | Provides essential salts, vitamins, and amino acids. | Far more complex than LB broth; often requires supplementation to be complete. |

| Fetal Bovine Serum (FBS) [26] | Provides a source of growth factors, hormones, and attachment factors. | A major source of variability and cost. The drive is towards serum-free media. |

| Trypsin/EDTA [6] | Enzyme solution used to dissociate adherent cells from the culture surface for subculturing. | Analogous to the function of lysozyme for breaking down bacterial cell walls, but used gently on living cells. |

| Dimethyl Sulfoxide (DMSO) [29] | A cryoprotectant added to freezing media to prevent ice crystal formation and cell lysis during cryopreservation. | Not typically used in standard microbial culture preservation. |

| Penicillin-Streptomycin (Pen-Strep) [25] | Antibiotic mixture added to media to prevent bacterial contamination. | Use is ubiquitous in research, but is avoided in biomanufacturing to ensure aseptic technique is paramount. |

| HEPES Buffer [27] | An organic chemical buffer that provides additional pH stability outside a CO₂ environment. | Useful for procedures that require extended time outside the incubator. |

For the microbiologist, mastering mammalian cell culture requires a paradigm shift from cultivating robust, independent prokaryotes to nurturing fragile, dependent eukaryotes. The key differences lie in the complexity of the nutrient media, the precision and constancy of the physical environment, and the specialized equipment required to maintain this environment. Success hinges on understanding that mammalian cells are not just "large microbes"; they require a simulated in vivo environment to survive and function. By appreciating these core differences and applying the rigorous, tailored techniques outlined in this guide, researchers can effectively leverage both microbial and mammalian systems to advance their scientific and biotechnological goals.

The foundation of modern microbiological and biomedical research rests significantly on the use of immortalized cell lines, which provide a consistent, renewable, and ethically preferable platform for experimentation. These cell lines, derived from various tissues and often from pathological conditions, allow researchers to dissect complex biological processes, model human diseases, and screen potential therapeutic compounds in a controlled in vitro environment. For microbiologists venturing into cell culture, understanding the origin, characteristics, and specific applications of these cellular tools is paramount to designing robust and reproducible experiments. This guide provides an in-depth technical examination of three cornerstone biological reagents: the ubiquitous HeLa cell line, the hormone-responsive MCF-7 breast cancer model, and the antibody-producing hybridomas.

The selection of an appropriate cell line is a critical first step in any research program, as each possesses a unique set of genetic, phenotypic, and functional attributes that determine its suitability for specific investigations. These attributes include, but are not limited to, morphology, growth kinetics, expression of specific receptors, genetic stability, and functional outputs. Misapplication or a lack of understanding of a cell line's specific properties can lead to erroneous conclusions, a problem compounded by the fact that cell lines can evolve and diverge when maintained in different laboratories. This guide aims to equip researchers with the necessary knowledge to navigate these common cell lines effectively, ensuring that their experimental models are aligned with their scientific questions.

HeLa Cell Line: The Immortal Workhorse

Origin and Historical Context

The HeLa cell line, the first immortal human cell line to be successfully maintained in continuous culture, was derived from a cervical adenocarcinoma of a 31-year-old African American patient, Henrietta Lacks, in 1951 [32] [33] [34]. The cells were taken without her knowledge or consent, a common practice at the time that has since sparked significant ethical discourse and led to major reforms in informed consent and patient rights in research [33] [34]. Named using the first two letters of her first and last name, HeLa cells exhibited an unprecedented ability to proliferate relentlessly in culture, doubling every 20-24 hours [33] [34]. This robustness, coupled with their easy cultivability and susceptibility to numerous viruses, quickly made them a fundamental resource for scientists worldwide, contributing to countless medical breakthroughs.

Key Characteristics and Technical Data

HeLa cells are characterized by their epithelial-like morphology and a set of unique biological properties that underpin their "immortality" and utility. They possess an active form of the enzyme telomerase, which prevents the telomere shortening that normally leads to cellular senescence, allowing them to bypass the Hayflick limit [33]. Genetically, HeLa cells are hypertriploid, with an average of 82 chromosomes (range 70-164) instead of the normal human diploid number of 46 [33]. This complex karyotype, featuring a high degree of aneuploidy and structural rearrangements (including "HeLa signature chromosomes"), is a result of their cancerous origin and transformation by Human Papillomavirus 18 (HPV18) [33] [34]. The initial biopsy contained HPV-18, the integration of which into the human genome was a key event in driving the cancer, a discovery that later contributed to the development of HPV vaccines [34].

Table 1: Key Characteristics of the HeLa Cell Line

| Parameter | Description |

|---|---|

| Origin | Cervical adenocarcinoma; 31-year-old female [33] [34] |

| Morphology | Epithelial-like [33] |

| Growth Properties | Immortalized; doubles every 20-24 hours; bypasses Hayflick Limit [33] |

| Karyotype | Hypertriploid, aneuploid; 70-164 chromosomes (avg. 82) [33] |

| Key Genetic Feature | Transformed by HPV-18; active telomerase [33] [34] |

| Susceptibility | High susceptibility to various viruses (e.g., Polio, Adenovirus) [33] |

Primary Research Applications

The applications of HeLa cells in research are vast and have been instrumental in numerous scientific milestones. Their use is documented in over 60,000 scientific articles, a number that continues to grow [34].

- Virology and Vaccine Development: HeLa cells were crucial for testing the first polio vaccine by Jonas Salk due to their high susceptibility to poliovirus [32] [33] [34]. They have since been used to study a wide array of viruses, including HIV, Zika, mumps, and measles, and were pivotal in research linking HPV to cervical cancer [33] [34].

- Cancer Biology: HeLa cells serve as a model for studying cancer mechanisms, testing chemotherapeutic agents like camptothecin, and investigating the effects of hormones and other compounds on cell proliferation [33].

- Genetics and Cell Biology: They were the first human cells to be successfully cloned and were used to create the first human-animal hybrid, facilitating early gene mapping efforts [34]. Research on HeLa cells has also contributed to our understanding of cellular aging and the effects of radiation and toxins [33] [34].

- Space Biology: In the 1960s, HeLa cells were sent into space to study the effects of zero gravity on human cells, where they were found to divide even more rapidly [34].

MCF-7 Cell Line: A Model for Hormone-Responsive Breast Cancer

Origin and Historical Context

The MCF-7 cell line is one of the most widely studied models of human breast cancer. It was established from a pleural effusion (a complication where cancer cells are found in fluid around the lungs) of a 69-year-old female patient with a metastatic breast adenocarcinoma [35]. The line is named after the Michigan Cancer Foundation, where it was developed. Unlike many other cancer cell lines, MCF-7 cells retain several characteristics of the original mammary epithelium, making them a valuable tool for investigating the biology of breast cancer and its response to therapeutic agents [35].

Key Characteristics and Technical Data

A defining feature of MCF-7 cells is their expression of the oestrogen receptor alpha (ER-α), which makes them a premier model for studying hormone-responsive (luminal A subtype) breast cancer [35]. They also express androgen, progesterone, and glucocorticoid receptors [35]. Morphologically, they exhibit an epithelial-like appearance and form characteristic dome structures in monolayer cultures due to fluid accumulation between the cell layer and the culture dish [35]. A critical consideration for researchers is the well-documented genetic and phenotypic instability of MCF-7 cells. Subpopulations and variants have emerged in different laboratories, leading to significant biological differences between MCF-7 lines obtained from different sources [35] [36]. These differences can include variations in chromosome makeup, growth rate, hormone receptor content, and tumorigenicity in mouse models [36]. For instance, one study found that different MCF-7 lines had varying growth rates and responses to estrogen and antiestrogen treatments, with one line (MCF-7 (ATCC)) being entirely unresponsive to such treatments despite having receptors [36].

Table 2: Key Characteristics of the MCF-7 Cell Line

| Parameter | Description |

|---|---|

| Origin | Pleural effusion of breast adenocarcinoma; 69-year-old female [35] |

| Morphology | Epithelial-like; forms dome structures [35] |

| Key Feature | Expresses oestrogen receptor alpha (ER-α) and other hormone receptors [35] |

| Genetic Stability | Genetically unstable; subpopulations and variants exist [35] |

| Research Caveat | Biological behavior can vary significantly between labs; source documentation is critical [36] |

Primary Research Applications

MCF-7 cells are primarily used as an in vitro model to study breast cancer biology, particularly the role of estrogen signaling in cancer proliferation and survival.

- Hormone Response Studies: Treatment with estrogen has an anti-apoptotic, growth-promoting effect on MCF-7 cells, while anti-estrogen drugs like tamoxifen inhibit proliferation and induce apoptosis [35]. This makes them an excellent model for screening and developing endocrine therapies.

- Drug Resistance Research: Numerous drug-resistant variants of MCF-7 have been intentionally developed, such as lines resistant to tamoxifen (MCF7/TAMR-7), fulvestrant (MCF7/182R-6), and aromatase inhibitors (MCF7/LetR-1) [35]. These sublines are invaluable for understanding the mechanisms of acquired resistance in breast cancer.

- General Cancer Biology: The line is used to study cancer cell invasion, metastasis, and the effects of various chemotherapeutic agents and natural compounds on cancer cell proliferation [35].

Hybridoma Cell Lines: Engines of Monoclonal Antibody Production

Hybridoma technology is a seminal method for producing monoclonal antibodies (mAbs). Invented by Köhler and Milstein in 1975 (for which they received a Nobel Prize in 1984), this technique involves the somatic fusion of antibody-producing B lymphocytes from an immunized animal (typically a mouse) with immortal myeloma cells (cancerous B-cells) [37] [38]. The resulting hybrid cells, termed hybridomas, combine the desired traits of both parents: the ability to produce a single, specific antibody from the B cell, and the capacity for indefinite growth ("immortality") from the myeloma cell [37] [38] [39]. This allows for the limitless production of homogeneous, clonally identical antibodies that recognize a single epitope on an antigen, providing unparalleled specificity compared to polyclonal antibody sera [37].

The Hybridoma Generation Workflow

The production of monoclonal antibodies via hybridoma technology is a multi-step process that requires careful execution at each stage. The following diagram and accompanying description outline the key procedural stages.

Diagram 1: Hybridoma generation and monoclonal antibody production workflow.

- Immunization: A laboratory animal (e.g., mouse) is injected with the antigen of interest over several weeks to stimulate a robust immune response and the production of antigen-specific B cells [37] [38].

- Cell Isolation & Preparation: Activated, antibody-producing B lymphocytes are isolated from the spleen of the immunized animal. In parallel, immortal myeloma cells are prepared; these are selected to be deficient in the hypoxanthine-guanine phosphoribosyltransferase (HGPRT) enzyme, making them sensitive to HAT selection medium [37] [38].

- Cell Fusion: The B cells and myeloma cells are fused together using a fusogen like polyethylene glycol (PEG) or by electrofusion, creating a heterogenous mixture that includes the desired B cell-myeloma hybrids (heterokaryons) [37] [38].

- Hybridoma Selection: The cell mixture is cultured in HAT (hypoxanthine-aminopterin-thymidine) selection medium. Aminopterin blocks the de novo nucleotide synthesis pathway. Unfused B cells have a short natural lifespan and die off. Unfused HGPRT-negative myeloma cells cannot use the salvage pathway and perish. Only the fused hybridomas, which possess the HGPRT enzyme from the B cell and immortality from the myeloma cell, survive and proliferate in HAT medium [37] [38].

- Screening & Cloning: The surviving hybridomas are screened (typically via ELISA) to identify clones that produce the desired antibody [37] [38]. Positive clones are then isolated and cloned, often by limiting dilution, to ensure that the resulting hybridoma line is derived from a single progenitor cell and is truly monoclonal [37] [38].

- Propagation & Production: The stable monoclonal hybridoma cell line can be propagated in vitro (in culture flasks) or in vivo (as ascites in mice) for continuous antibody production [37]. The cells can also be cryopreserved for long-term storage [37].

Primary Research and Clinical Applications

Monoclonal antibodies produced via hybridoma technology have revolutionized biomedical research, diagnostics, and therapeutics.

- Research and Diagnostics: mAbs are indispensable tools for identifying and characterizing cellular markers (e.g., the cluster of differentiation (CD) markers), distinguishing between morphologically similar diseases in histopathology, and detecting occult metastases [38]. They are also used in techniques like ELISA, flow cytometry, western blotting, and immunoaffinity purification [37] [38] [39].

- Therapeutics: Monoclonal antibodies are used to treat a wide range of conditions, including cancer, autoimmune diseases, and infectious diseases [37] [39]. Early murine mAbs posed a risk of eliciting a human anti-mouse antibody (HAMA) response, which led to the development of chimeric, humanized, and fully human antibodies to reduce immunogenicity [40] [39].

Comparative Analysis and Selection Guide

Choosing the correct cell line is a strategic decision based on the research question. The table below provides a direct comparison of the three cell lines to aid in this selection.

Table 3: Comparative Guide to HeLa, MCF-7, and Hybridoma Cell Lines

| Feature | HeLa | MCF-7 | Hybridoma |

|---|---|---|---|

| Primary Research Use | Virology, general cell biology, cancer biology, toxicology | Hormone-responsive breast cancer biology, drug resistance | Monoclonal antibody production, immunology |

| Defining Functional Output | N/A (General model system) | Hormone-induced signaling and proliferation | Secretion of a specific, homogeneous antibody |

| Key Receptors/Markers | Susceptibility to virus receptors (e.g., CD4 for HIV) | Oestrogen receptor alpha (ER-α), Progesterone receptor | Surface immunoglobulins (parental B cell) |

| Growth Considerations | Very rapid, adherent, highly robust | Slower, adherent, hormone-sensitive for proliferation | Can be adherent or suspension; requires screening |

| Major Technical Caveats | Notorious for contaminating other cell cultures | High variability between lab stocks; requires defined frozen stock | Time-consuming initial development; potential for murine immunogenicity |

Essential Reagents and Protocols

The Scientist's Toolkit: Key Research Reagent Solutions

Successful cell culture requires a suite of reliable reagents. Below is a list of essential materials for working with these cell lines.

Table 4: Essential Research Reagents for Featured Cell Lines

| Reagent / Material | Function / Application |

|---|---|

| HAT Media (Hypoxanthine-Aminopterin-Thymidine) | Selective media for killing unfused myeloma cells and allowing only hybridomas to grow after cell fusion [37] [38]. |

| Polyethylene Glycol (PEG) | A fusion-promoting agent used to fuse the plasma membranes of B lymphocytes and myeloma cells to create hybridomas [37] [38]. |

| Myeloma Fusion Partner Cell Lines | Immortal, HGPRT-negative cells (e.g., SP2/0, NS0) designed for efficient fusion and hybridoma formation [40] [39]. |

| Phenol-Red-Free Media | Essential for hormone-related studies on MCF-7 cells, as phenol red is a weak estrogen and can interfere with experimental results [35]. |

| Estradiol / Tamoxifen | Estradiol is used to stimulate proliferation of MCF-7 cells via ER-α; Tamoxifen (an anti-estrogen) is used to inhibit growth and induce apoptosis [35]. |

| Fetal Bovine Serum (FBS) | A standard supplement for cell culture media, providing growth factors, hormones, and lipids. Charcoal-stripped FBS may be used for hormone studies to remove steroids [35]. |

| Cryopreservation Media | A solution containing a cryoprotectant like DMSO, used for the long-term storage of stable cell lines and hybridomas in liquid nitrogen [37]. |

After hybridoma selection in HAT medium, screening for antigen-specific antibody production is critical. ELISA is a common primary screening method.

- Coating: A 96-well plate is coated with the target antigen diluted in a coating buffer and incubated overnight.

- Blocking: The plate is washed and then blocked with a protein solution (e.g., BSA) to prevent non-specific binding of antibodies.

- Primary Incubation: Hybridoma culture supernatant is added to the wells and incubated, allowing any specific antibodies to bind to the immobilized antigen.

- Secondary Incubation: A secondary antibody (e.g., enzyme-labeled anti-mouse immunoglobulin) is added, which binds to the primary antibody from the hybridoma.

- Detection: A chromogenic substrate for the enzyme is added. The formation of a colored product indicates the presence of an antigen-specific hybridoma in the well [38].

HeLa, MCF-7, and hybridoma cell lines represent powerful and versatile tools in the microbiologist's and biomedical researcher's arsenal. Each serves a distinct purpose: HeLa as a robust general model, MCF-7 as a specific model for hormone-responsive cancers, and hybridomas as biological factories for precise immunological reagents. A deep understanding of their origins, characteristics, and inherent limitations—such as the genetic drift in MCF-7 lines or the immunogenicity of murine antibodies—is fundamental to their effective and responsible application. By selecting the appropriate cell line and applying rigorous culture and experimental protocols, researchers can continue to leverage these invaluable resources to drive scientific discovery and therapeutic innovation forward.

Essential Methods and Industrial Applications from Lab to Production

The maintenance of healthy and proliferative cell cultures is a cornerstone of biomedical research and drug development. For adherent cell lines, regular passaging, also known as subculturing or splitting, is an indispensable technique. This process involves the detachment of cells from the culture vessel surface and the transfer of a small fraction to a new vessel containing fresh growth medium [41]. The primary purpose is to enable continued propagation by providing ample space and nutrients, thereby maintaining cells in their exponential growth phase (log phase) and preventing the stress and decline associated with over-confluency [6] [41]. Mastering this technique is essential for ensuring experimental reproducibility, maintaining genetic and phenotypic stability, and generating reliable data in cellular and molecular biology studies [42]. This guide provides a detailed, step-by-step protocol for the trypsin-based passaging of adherent cells, framed within the essential practices of animal cell culture.

Understanding Cell Growth and When to Subculture

The Growth Phases of Cultured Cells

Adherent cells in culture follow a characteristic growth pattern composed of four distinct phases, as illustrated in the growth curve below [6] [41]. To ensure viability and genetic stability, cell lines must be maintained in the exponential growth phase and subcultured before they enter the stationary phase [6].

The log phase is the optimal window for subculturing. Passaging cells before they reach 100% confluence is critical because normal cells exhibit contact inhibition, ceasing growth when the surface is covered [41]. Allowing cells to become overly confluent can lead to prolonged recovery times, reduced viability, and in some cases, irreversible senescence [43].

Key Indicators for Subculturing

Regular microscopic observation is required to determine the optimal time for passaging. Key indicators include [41] [44]:

- Confluency: Most adherent cell lines should be passaged when they reach 70-90% confluency.

- Medium Color: A rapid yellowing (acidification) of the medium, caused by increased metabolic waste (e.g., lactic acid), indicates a high cell density and the need for a medium change or subculture.

- Growth Phase: Cells should be subcultured while they are in the mid to late log phase of growth.

Materials and Reagents

The following table summarizes the essential materials and reagents required for the trypsinization and subculturing process [41] [44] [45].

Table 1: Essential Reagents and Materials for Passaging Adherent Cells

| Item | Function / Purpose |

|---|---|

| Cell Culture Vessels (e.g., T-flasks, dishes) | Surface for cell attachment and growth. |

| Complete Growth Medium | Provides nutrients, growth factors, and serum for cell proliferation. |

| Balanced Salt Solution (BSS)(e.g., PBS without Ca²⁺/Mg²⁺, HBSS) | Washes cells to remove residual serum and ions that inhibit trypsin. |

| Trypsin-EDTA Solution(e.g., 0.05%–0.25% trypsin) | Proteolytic enzyme detaches cells by digesting adhesion proteins. EDTA chelates calcium and magnesium to enhance cell detachment. |

| Trypan Blue Solution | Vital dye used to distinguish live (unstained) from dead (blue) cells during counting. |

| Hemocytometer or Automated Cell Counter | Device for determining cell concentration and viability. |

| Serum-containing Medium or Trypsin Inhibitor | Inactivates trypsin to prevent over-digestion and cell surface damage. |

| Centrifuge Tubes | For collecting and centrifuging cell suspensions. |

Step-by-Step Passaging Protocol

The following workflow outlines the complete process for passaging adherent cells, from preparation to seeding of the new culture.

Pre-Procedure Preparation

- Warm Reagents: Thaw and warm all reagents, including trypsin-EDTA, balanced salt solution (BSS), and complete growth medium, in a 37°C water bath for approximately 30 minutes. Avoid prolonged exposure of reagents to high temperatures [44].

- Label Vessels: Pre-label new culture vessels with the cell line, passage number, date, and your initials.